Early Onsite Issues

Explore Timeline

Transfer of Process Water

Liner Issues

Unreported Spills

Heavy Metals in Stormwater Discharge

Early Onsite Issues

Rockwool has been operating since July 7, 2021 and yet there are already issues that may threaten the groundwater and the water resources of the region. The DEP has failed to take action to protect the water resources or human health.

DEP site inspection reports of Rockwool and its correspondence from June and July of 2021 reveal that Rockwool transferred Process (polluted) water from the Reuse Pond to the Stormwater Pond in direct contradiction to its permit; had unreported spills of unknown quantities of unknown substances with unknown effect on the groundwater; and that the pond liners are allowing water to accumulate under them and require repair in both ponds in multiple locations.

Despite all of this the DEP failed to issue even one notice of violation to Rockwool during either of the most recent inspections. These inspections were the first in over a year and were only carried out because the Foundation requested them.

Now the DEP has informed the Foundation that it will no longer communicate with us about Rockwool. This abdication of its duty to the public by the DEP is frankly not surprising but it is incredibly frustrating.

West Virginia has been delegated the duty and responsibility of administering the National Pollutant Discharge Elimination System (NPDES) program in West Virginia. The NPDES program under the Clean Water Act protects the water quality of waters of the US (navigable waters) and waters of the State (surface and groundwater). As the administrator, the DEP grants permits for the discharge of water and monitors enforcement and compliance with permits and state and federal laws and regulations. While the EPA maintains ultimate control of the program in states with delegated power to administer the NPDES program, the regional EPA is typically resistant to get involved in matters of permitting and enforcement. As such, we must engage the DEP, and we must demand good faith transparency and diligence from the DEP.

Why do these issues matter?

Each of these issues stands to carry pollution to the groundwater. The groundwater at this site is used by all of the surrounding residents through wells for all purposes. This groundwater also travels rapidly to multiple surface streams via springs and is all deposited in the Potomac directly or by the Opequon and Shenandoah. In this way, these issues effect the water resources of the region.

Timeline

Click through the timeline below by clicking on the date on the left to see the correspondence trail from Rockwool to the DEP and our responses.

- May 24, 2021

- June 2

- June 2 and 21

- June 23

- June 24

- June 25

- June 29

- July 2

- July 7

- July 14

- July 16

- August 24

- August 31

- September 1

- September 2

- September 24

- October 14

- November 24

Rockwool letter to the DEP – A valve is broken Rockwool will have to excavate it to access it. This valve controls the flow of water from the Stormwater Pond to outlet number one where the water from the Stormwater Pond discharges to the environment and infiltrates into the ground water.

Read the Rockwool letter to the DEP (PDF).

Rockwool letter to the DEP – The issue with the valve is identified.

Rockwool found that the valve was stuck in the open position and it devised a fix for it but this would require ordering parts.

Rockwool posted videos on their Facebook page that seem to demonstrate stormwater practices in direct contradiction to its permit.

June 2 Video:

June 21 video:

Jefferson County Foundation sent a complaint to the DEP asking that it perform an inspection of the Rockwool site. The Foundation asked several specific questions about what can be seen in the video. Several of them have gone unanswered still today.

DEP performed an inspection of the Rockwool site. A construction stormwater permit “inspector in training” (according to the July 2020 WVDEP employee directory) inspected the site and found that indeed Rockwool was transferring process (polluted) water via hoses and pumps from the Reuse Ponds to the Stormwater Pond. Rockwool’s Stormwater Pollution Prevention Plan (SWPPP – part of its permit registration) states referring to the Reuse Pond, “At no point will water be discharged from this pond.” Rockwool was not issued a notice of violation and not even asked to stop the operation.

The Foundation did not receive this report until July 2 — nine days after the inspection.

Read the inspection report from the DEP (PDF).

Rockwool sent the DEP a letter notifying the Agency that it would be conducting camera inspections of its underground stormwater conveyance systems. It is unknown what precipitated this inspection by Rockwool: a leak, a concern about quality of instillation, or something else. More alarmingly, this letter also notified the DEP that there were problems with the pond liners that required repair. These problems were apparently allowing water to accumulate under the pond liner. These problems were in both ponds and in multiple locations. There was not enough information in this letter to determine: exactly what the damage was; how it had occurred; how it had been discovered; how it would be fix and prevented from happening again; what water was accumulating under the liners (ie was it polluted water); or if the groundwater was effected.

Rockwool sent the DEP a letter notifying them that it had a leaky fire hydrant that was accumulating water around it and it planned to fix it.

Jefferson County Foundation was sent the inspection report from DEP (nine days after the inspection). The Foundation sent the DEP a second letter asking that they do a second inspection that address all of the Foundation’s concerns and was performed by a qualified inspector familiar both with the Multi-sector Stormwater General Permits and Rockwool’s permit registration.

The DEP performed a second inspection of the Rockwool site. This inspection was performed by the original inspector and a second inspector that was apparently more qualified. This inspection again found that Rockwool had transferred the process water from the Reuse Pond to the Stormwater Pond. It also found that Rockwool had had spills that it had not reported as required by law. Still the DEP did not give Rockwool a notice of violation, inquire as to how they intended to remove the pollutants from the stormwater pond before returning it to normal use, or even mention the defects in the pond liners.

The Foundation did not receive this report from the DEP until July 16 — eight days after the inspection.

As Jefferson County Foundation had still not received a copy of the inspection report from the July 7 and was unaware if an inspection had even occurred, the Foundation sent a letter to the DEP inquiring if an inspection had been done and if so where the results were.

The above-mentioned letters from Rockwool to the DEP on May 5, June 2, 25, and 29 were finally made public on the Application Xtender website.

The DEP sent the Foundation a letter letting us know they would no longer be communicating with us about Rockwool until final reports were available, because of ongoing litigation.

Read the letter from the DEP to the Foundation (PDF).

The Foundation sent the DEP a letter objecting to this abdication of its responsibilities that is unsubstantiated by law or legal president.

Read the letter from the Foundation to the DEP (PDF).

The DEP sent the Foundation the inspection report from the July 7, 2021 inspection.

The Foundation sent another complaint to the DEP citing possible issues that are not described in or in accordance with Rockwool’s Multi-Sector Stormwater General Permit (MSGP) registration materials.

The Foundation writes to the DEP and EPA regarding the elevated aluminum levels detected in Elk Branch Stream #1.

Read the letter from the Foundation to the DEP and EPA here.

After over two weeks, the West Virginia Department of Environmental Protection (DEP) finally responded to our numerous requests for an inspection report of the Rockwool facility after several apparent observed violations. The DEP inspectors did not inspect the areas of concern outlined in our complaint themselves. Rather than adequately responding to our concerns in our complaint and actually inspect the locations outlined in our complaint, the DEP simply let Rockwool supply “nothing to see here” answers to our concerns. The DEP also defers to Rockwool engineers to supply an inspection report on a repair to the pond liners. This is why our case in front of the WV Environmental Quality Board (EQB) regarding Rockwool’s stormwater management practices is so essential.

Read the DEP inspection report.

Read Rockwool’s response to the issues outlined in our complaint.

Rockwool sends a letter to the DEP alerting it that there will be a stormwater improvement project in one section of the facility.

Rockwool sends another letter to the DEP alerting them about another stormwater improvement project at the Ranson facility.

Read the letter from Rockwool to the DEP on September 24, 2021.

Rockwool sends another letter to the DEP regarding exceedances of Aluminum and Iron at Outlet 002.

Rockwool sends a letter to the DEP in response to Outlet 002 and plans to take corrective action by April 30, 2022.

Transfer of Process Water from the Stormwater Pond

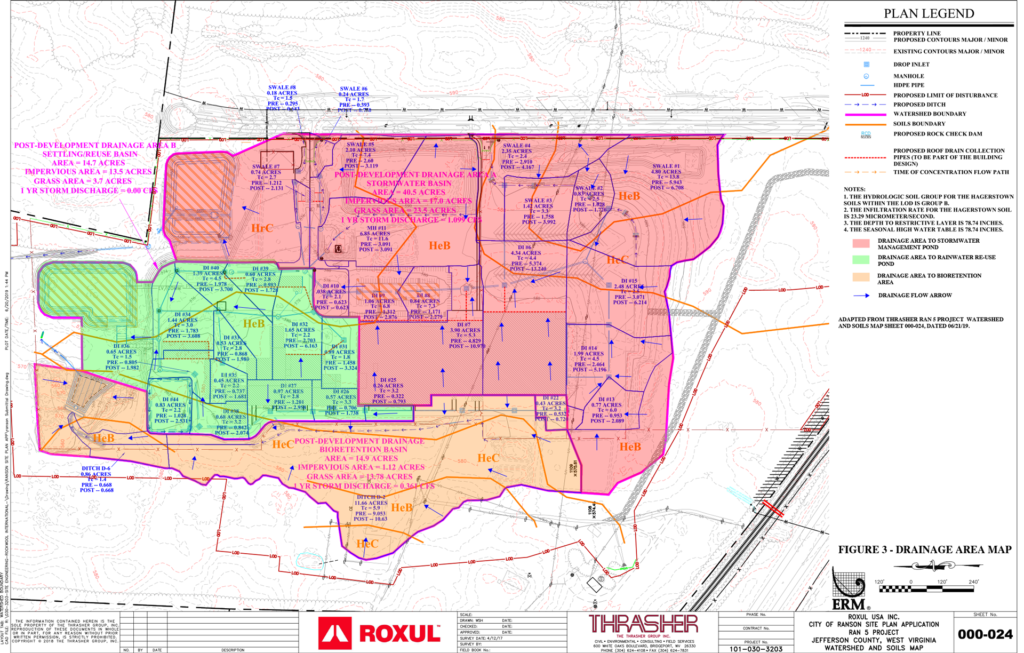

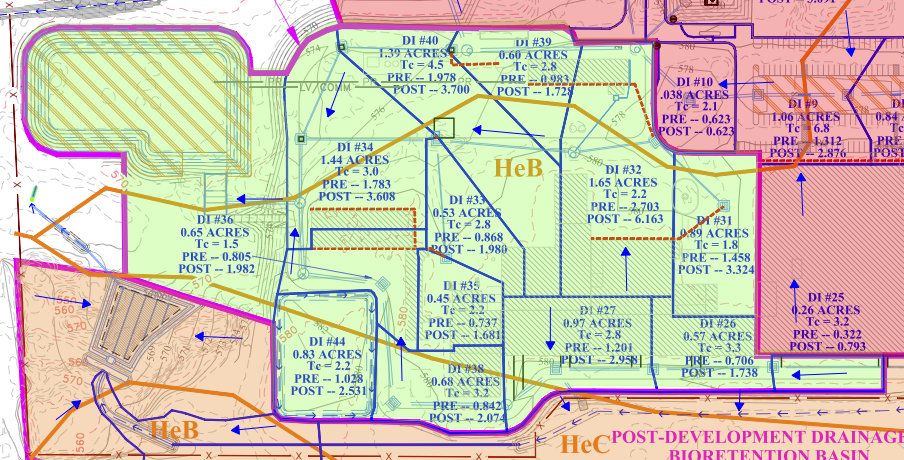

On the map above, each color denotes a different drainage area.

Pink Highlighted Area:

The top drainage area in pink is more than 40 acres and drains stormwater from rooftops, parking lots, grassy areas and some roads into the stormwater pond. This water is considered “clean” stormwater because it is from the cool or clean end of the facility where the finished goods are handled. This water does still carry pollutants, though. The air emissions contain some pollutants like PM10 that fall to the ground on all surfaces at the site. These pollutants are entrained in the stormwater and carried wherever it goes. How much pollutants? Rockwool PSD (prevention of significant deterioration) Air Permit seems to suggest it is about 76 tons of PM10 per year. What is in the PM10 from Rockwool? The PM10 caries hazardous pollutants including:

- Sulfuric Acid (H2SO4) 16.4 tons per year

- Methanol (CH4)) 104 tons per year

- Phenol (C6H5O) 98.9 tons per year

- Formaldehyde (HCHO) 67.7 tons per year

- Carbonyl Sulfide (COS) 1.7 tons per year

- Hydrogen Fluoride (HF) 1.7 tons per year

- Hydrogloric Acid (HCl) 1.3 tons per year

- Hexane (C6H14) 0.3 tons per year

- Benzene (C6H6) 0.1 tons per year

- Lead (Pb) <0.1 tons per year

Green Highlighted Area:

The drainage area marked in green drains the “dirty” or hot end of the facility. This stormwater contains process water and far more pollutants. This is because it drains the floor drains from the truck washing station, the area around the raw material storage area, the Melt for Reuse area, and the end of the facility where the product is made, where more fugitive emissions are expected to fall to the ground and be entrained in stormwater. This stormwater drains into the Reuse Pond. The water in the Reuse Pond is process water as defined by the EPA. The EPA defines process water as “Process Wastewater means any water which, during manufacturing or processing, comes into direct contact with, or results from the production or use of any raw material, intermediate product, finished product, byproduct, or waste product.” (40 CFR 122.2) This water washes over and therefore comes in direct contact with the intermediate products in the melt for reuse area. What is included in this material? It includes blast furnace slag, converter slag, high-aluminum kaoline clay, aludross (byproduct of aluminum smelting), coal, pet coke, coke fines, anodes, dedusting oil.

Melt for reuse are or B170:

In the image above, see the large piles of material. This area, according to the air permit, is meant to store Melt for Reuse (which is material from the Melting Furnace). Once a week, the Melting Furnace is shut down and this allows the residual melt still in the furnace to harden, which is then removed and stored here. Once a quarter, a portable crusher (machine that makes gravel at a quarry) is brought in and crushes this material so that it can be reused in the melting furnace. It is again then stored here until it is reused. During that time, rain falls on this material and eroded pollutants from this pile are entrained in the stormwater. The stormwater is collected by the gutter around the outside of the area and goes into the drop inlet (noted by the black sock around the grate), then is conveyed to the Reuse Pond. In this way, the Melt for Reuse area contributes a significant amount of pollution to the Rainwater for Reuse Pond. Rockwool’s videos and the inspection reports show that Rockwool is taking process (polluted) water from the Reuse Pond and transferred it to the Stormwater Pond. The Stormwater Pond outlets to the environment where the discharged water and any pollutants it may carry infiltrates into the groundwater. While the inspection report stated that none of this water discharged to the environment, no information was given as to how this was achieved over several weeks when the rain was so heavy, and the valve that is meant to control outflow from this pond was broken.

Liner Issue

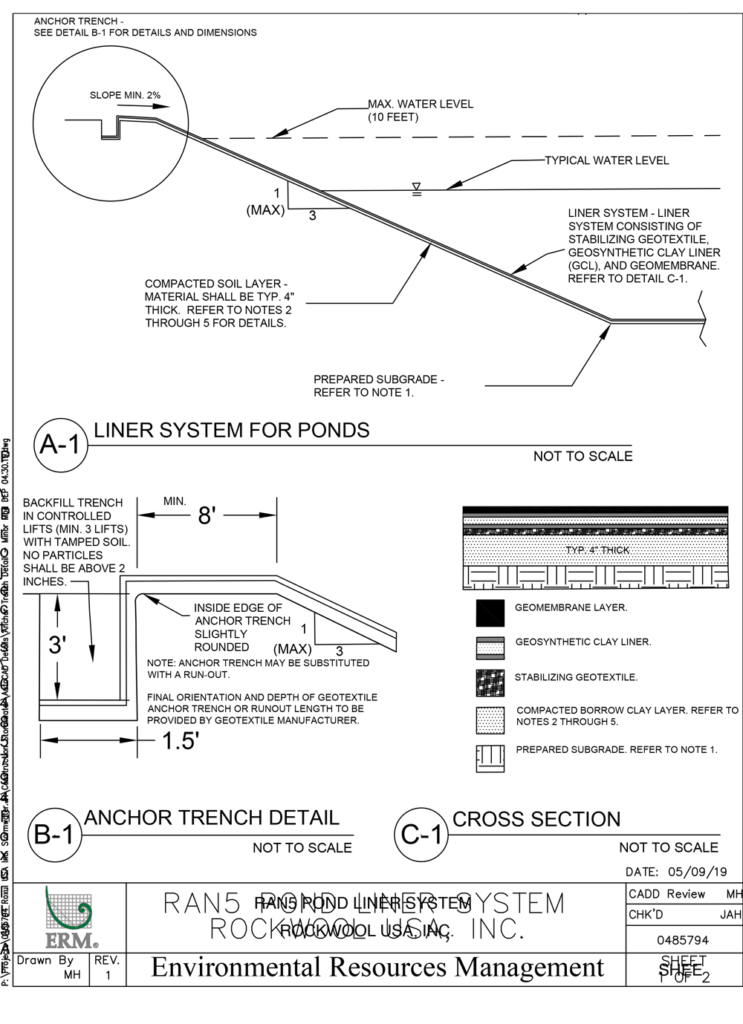

According to the June 25, 2021 letter from Rockwool to the DEP, the liner in both the Stormwater Pond (pink shaded area above) and the Reuse Pond (green shaded area above) are having issues that require repair. Water is being allowed to accumulate under the liner. No information is given as to how this is occurring or what water is accumulating.

This diagram (at right) shows how the liner is installed. Notice that it would be difficult for water to enter under the edge of the pond if it were installed according to this diagram. The pond liner over laps the top of the pond by 8 feet and then is buried underground with a 3 foot by 1.5 foot footer.

During Rockwool’s construction, the DEP asked Rockwool to install a double liner in the ponds with an interstitial leak detection system. Rockwool refused citing the cost of the liner.

Rockwool Discharges High Levels of Aluminum

Rockwool Submitted its electronic Discharge Monitoring Report to the DEP on July 20, 2021. It revealed that in the second quarter of 2021 Rockwool reported an elevated aluminum (4.2 mg/L or 4200μg/L) and elevated iron (6.1 mg/L or 6100μg/L) in the stormwater discharge from outlet 002. It did not report any measurements for outlet 001, reporting instead that there was no discharge from 001 during Q2. However, Rockwool had elevated aluminum in the stormwater discharge of outlet number 001 during the first quarter of 2021.

Source of the aluminum

In a letter to the DEP dated July 20, 2021 Rockwool explained it thought the source of the elevated aluminum was related to “land disturbances still undergoing stabilization.” However, this explanation does not make sense. For a majority of construction, a majority of the 100-acre limit of disturbance was disturbed and unvegetated. If the aluminum was from the sediment run off, it would have been elevated throughout construction. The baseline tests done on wells and springs as part of the Foundation’s water testing program would likely have detected aluminum during construction.

Rockwool’s raw materials are high in aluminum. Rockwool uses bauxite and aluminum slag among other materials that are known to be high in aluminum. Rockwool’s Melt for Reuse and final product is at least 18% aluminum oxide[1], meaning the Melt for Reuse material should also be approximately 18% aluminum. This information is based on a 2006 article “Alumina in a Spin” in the periodical Industrial Minerals, where Rockwool is showcased as the world leading manufacturer of mineral wool; Rockwool’s final product is composed of at least 18% aluminum oxide (bioavailable form of aluminum). Rockwool states “the end product chemistry is set in stone.”

Contamination of stormwater

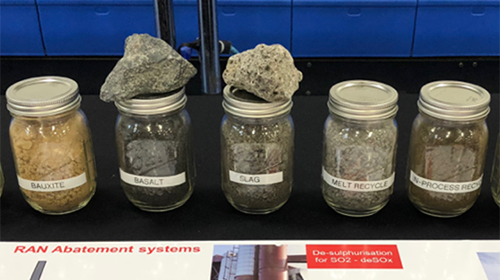

The stormwater from the Melt for Reuse area is meant to drain into the Reuse Pond. This Pond does not discharge into the environment (it is not designed to); instead, the water is drawn back into the process. This is supposed to stop any contaminants from the Melt for Reuse area from being discharged into the environment. However, the inadequate design of the Melt for Reuse area is allowing stormwater from the Melt for Reuse area to spill over into the grass area that drains into outlet 002. (see pictures below) It also appears that in addition to Melt for Reuse raw materials (that look similar to aluminum slag and bauxite) (see picture of jars below) are being stored in the Melt for Reuse area.

As described above, the raw material areas of the facility (green) drain to the Settling Pond of the Reuse Pond where contaminants may settle out. Rockwool must periodically clean this settling pond out. The protocol for this is described in Rockwools Storm Water Pollution Prevention Plan (SWPPP). This protocol states that Rockwool will dry out the settling pond before cleaning it out, then the material will be transported back to the Melt for Reuse area. It appears from the Foundation’s drone photos that this is not being done. It appears as though the material is being cleaned out while water is still present in the settling pond. (pic) It also appears as though some portion of the material is being spilled on the ground where these pollutants can be easily carried into the groundwater through indirect infiltration or carried into outlet 002.

Rockwool’s Operational Stormwater Permit

Unfortunately, Rockwool’s Operational Stormwater Permit (MSGP) does not address these issues. The inadequate nature of the stormwater design at the Melt for Reuse area was addressed by the permit reviewer during the permitting process. The inadequate design of the settling pond and the inadequate procedure for cleaning the settling pond out was not addressed adequately by the permit reviewer. The material in the settling pond was not addressed as a source reasonably expected to effect stormwater.

Rockwool failed to include the Melt for Reuse area, the Melt for Reuse material itself and other material stored there, the settling pond for the Reuse Pond and the procedure for cleaning this pond out as sources that could reasonably be expected to contaminate or pollute stormwater as required by the permit. Rockwool failed to characterize the chemical nature of the materials stored in the Melt for Reuse area as required by the permit. Thus, Rockwool never provided the information to the DEP that the material was high in highly soluble aluminum oxide that was likely to dissolve in and contaminate the stormwater.

This permit is simply inadequate to protect the surface and groundwater from the pollutants at Rockwool. Rockwool failed to provide true accurate and complete information when applying for the MSGP registration it currently has. The DEP permit reviewer failed to require Rockwool to adequately address the obvious engineering issues in the stormwater design and failed to require that Rockwool provide adequate information to satisfy the permit requirements.

This is why the Foundation’s appeal of this permit and continued work at the DEP and EPA is so critical. And why further enforcement action will likely be necessary.

Groundwater contamination

As part of the Foundation’s Water Monitoring Program several springs around Rockwool were tested for Aluminum prior to Rockwool’s operation. Aluminum was below the detection limit (100μg/L Minimum Detection Limit) in these locations prior to Rockwool’s operation. Repeat sampling was done in August of 2021 following Rockwool’s discharge monitoring results. In this sampling Elk Branch Spring #1 was found to have elevated aluminum levels (189μg/L). The EPA limit for drinking water is 200μg/L. In testing done September of 2021, the same Elk Branch Spring #1 was found to have even higher elevated aluminum levels (3800μg/L), which is more than 19 times the EPA limit for drinking water and 20-fold the previous result.

Aluminum has several adverse health effects. A recent review article is here for your review.

What can you do?

Donate to the Foundation Legal Fund. Especially when new information like this comes to light, we need the help of technical experts and lawyers which increases our financial needs. And if you feel comfortable doing so, share this information with your local elected officials and ask them to help urge the WV DEP to keep our water safe and clean.

[1] According to a 2006 article “Alumina in a Spin” in the periodical Industrial Minerals, where Rockwool is showcased as the world leading manufacturer of mineral wool, Rockwool’s final product is composed of at least 18% aluminum oxide (bioavailable form of aluminum). Rockwool states “the end product chemistry is set in stone”.