Mountaineer Gas, the only distributor of natural (fracked) gas in the Eastern Panhandle of West Virginia, needs to find a way to supply gas to Rockwool, the stone wool insulation plant being built in Jefferson County. Mountaineer Gas is seeking two to three locations in the eastern side of Berkeley County, near the Jefferson County line, on which to build injection stations. The natural gas would be trucked to the site and then decompressed and injected to the pipeline. It could also be stored on site.

The Baseline Issue

Mountaineer Gas has promised to supply the new insulation manufacturing facility in Jefferson County – Rockwool – with enough natural gas to run its operation. The problem is they don’t currently have a pipeline source for this much natural gas. Mountaineer Gas plans to use a virtual pipeline and peaking/staging stations in your neighborhood to solve the problem. Read on to see how your neighborhood will be affected and how you can take action.

A Virtual Pipeline

Over the last several years, new transmission and distribution gas pipelines have come under heavy scrutiny and opposition. This opposition stems from, among other things, the negative local environmental effects of the pipelines themselves and also from the negative environmental effect of the extraction technique known as fracking. There is also increased recognition that as a society we need to use less fossil fuels and more renewable energy in order to achieve net zero greenhouse gas emissions and eventual drawdown of greenhouse gases. In light of this, many see building new gas supply infrastructure for a declining commodity is wasteful, especially when the cost is put on the backs of ratepayers.

Gas companies have solved this problem by introducing virtual pipelines. In a virtual pipeline, a truck designed to carry compressed natural gas is filled at a source location. The truck then drives to the site where gas is needed and the gas is decompressed off of the trucks. Normally, this happens at the end user, so you may be thinking that Mountaineer Gas plans to have the trucks drive to Rockwool to decompress and off load the gas. However, this is not what Mountaineer Gas is planning. Instead Mountaineer Gas is seeking to build between one and three what they call peaking/staging stations. At these stations trucks carrying compressed natural gas (CNG) or liquid natural gas (LNG), are off loaded by decompressing and warming the fracked gas. Then the gas is injected into the underground pipeline, and it is carried to its end destination in this case Rockwool. The fracked gas may also be stored on site.

Peaking/Staging Station in Your Neighborhood

Mountaineer Gas has already proposed to build one of these stations on the old landfill site. In this proposal, Mountaineer Gas requested 24-hour truck access to the site and the ability to store gas on site. Typically, when these types of stations are introduced, the gas company tries to assure the usually concerned public that trucks will only run during daylight hours and no gas will be stored on site. Mountaineer Gas is offering no such assurances to your neighborhood. These sites are also typically not in locations with such high density of housing as your neighborhood.

Is it a Peaking Facility?

The short answer is no. Read this and the next section to find out why.

Peaking facilities only operate in the winter (heating season), normally from November 1 through March 31. CNG tankers are delivered to an injection station in late October and removed by early April. No trailers are on site during the non-winter months. In fact, all of the equipment (depressurization unit and associated injection equipment) is removed each fall and set back up each spring. The only remaining item is a pipeline cap.

Customer needs change by the season, by the day, and even by the hour. On a cold winter day, for example, residential customers can use seven times the amount of natural gas used on an average summer day. That is why a distributor like Mountaineer Gas who is running a retail gas system dangerously close to its maximum capacity, would look to install a peaking facility.

Non-peaking facilities operate year-round and are called Supplemental Supply plants. They are for the case where shortages of natural gas are expected to occur throughout the year, due to over-promised demand. Rockwool in Jefferson County, when it becomes operational will use an average total daily gas consumption of 1.61 MMCf/d.1

[1] Mountaineer Gas Company letter to J. Reisenweber, JCDA, April 3, 2017.

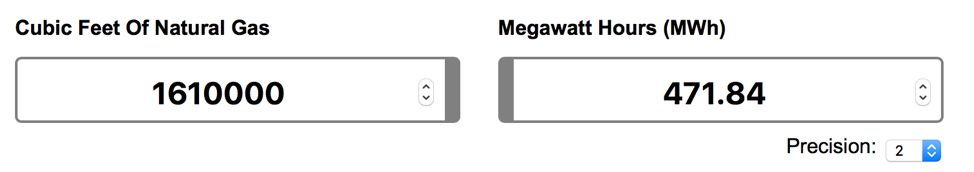

How much energy does Rockwool’s Gas Consumption represent?

Rockwool’s average daily gas consumption of 1.61 MMCf/day is equivalent to 472 Megawatt Hours. A megawatt hour (MWh) is a unit of energy. It is a measure of the actual amount of power consumed or produced by one megawatt expended for a period of one hour. A megawatt (MW) is a unit of power. It describes the rate at which power is being consumed or produced by a circuit at any given moment in time. A megawatt is equivalent to one million watts. As a general rule of thumb, each MW of a typical coal or natural gas power station’s capacity can supply around 650 average homes. Rockwool’s daily gas use is the equivalent of powering 12,783 homes.[1]

Mountaineer Gas has 4,900 residential customers in Berkeley County. That means that just supplying Rockwool is equal to almost tripling their residential customer base! And remember, as shown earlier, the current natural gas supply available to Mountaineer Gas is limited, due to the small size of the trunk line from Winchester, VA. They are operating a close to maximum capacity already. So where is all this gas coming from to feed Rockwool’s daily demand? This is why Mountaineer Gas is desperate to construct two to three, year-round, non-stop operational CNG injection stations as close to Rockwool’s existing pipeline as they can get in Berkeley County.

[1] 472 MWh/24 hrs = 19.66 MW; 19.66 MW x 650 homes = 12,783 homes

The Problems and Risks

There are several notable risks associated with this type of fracked gas injection station.

More Heavy Trucks

First, it will increase heavy truck traffic in your neighborhood, and you and your children and their school buses will be sharing the road with heavy trucks carrying dangerous material. Rockwool will require between 1.6 and 3.6 mmcf of fracked gas per day for operation.

How many CNG trucks are we talking about?

“A virtual pipeline is a natural gas supply process in which natural gas is sourced from a transmission pipeline, dried, chilled, and compressed to 3,600 psi. The compressed gas is then loaded into high-tech, carbon fiber tubes housed within a trailer. The CNG is then transported to a customer site where it is offloaded from the trailer, warmed, and decompressed, thus reducing the psi to accommodate a customer’s specific requirements.”[1]

Trailers come in all sizes: they range from a 20-foot trailer that carries from 120-140 Mcf of CNG to a 45-foot trailer that can hold a maximum 549 Mcf CNG.[2] Quantum Fuel Systems, a CNG trailer manufacturer in California, claims the highest capacity: “VP high-capacity, super-lightweight CNG storage tanks (are) packed into a 45-foot-High-Cube shipping container. The VP trailers can be filled at major gas pipelines then driven to customers for continual, uninterrupted supply of CNG. The VP trailer stores gas at up to 5,000 psi enabling a single container to hold up to 645,014 SCF (645 Mcf), the highest capacity in the industry.”[3]

The reality, however, is that road weight limits restrict the use of 645 Mcf trailers to places where truck weight limits can exceed 80,000 lbs. (excludes most US Highways). For routes restricted to 80,000 lbs., customers can use a “VPLite” model with 470 Mcf CNG capacity.

No one knows yet which size trailers Mountaineer Gas will be contracting to use. In order to calculate the number of trailers and how often they would be going into the Berkeley County neighborhoods, we need to make some assumptions. We also need to also know how fast the gas from the trailers can be decompressed and injected into the pipeline. There are many different types of station designs, but typical decompression rates fall in the range of 40-75 Mcf per hour.[4] As we know, Rockwool needs an average gas supply of 1.61 MMcf/day. That equals 1,610 Mcf/day, or 67 Mcf/hour, which is right in the range of what a CNG decompression skid can deliver. Let’s assume that is the CGN injection station flow rate. Also assume a VPLite-type of trailer, with 470 Mcf capacity. That one trailer will be empty in 7 hours. To provide Rockwool with uninterrupted power (the factory operates 24 hours a day, 7 days a week), a minimum of 4 trailers would be needed in every 24-hour passage of time. As one empties, the other takes over. That first truck leaves, to be replaced with another truck. So, round the clock, a fleet of at least eight 80-foot-long, 80,000-pound semi-trailer trucks, carrying highly compressed natural gas coming and going along small secondary roads in the vicinity of the Martinsburg VA Medical Center and the Hospice of the Panhandle.

[1] https://www.plantengineering.com/articles/virtual-pipelines-to-the-rescue/

[2] https://www.thigpenenergy.com/fleet-services-lng-cng-trucks-trailers/

Will Eight CNG Trucks a Day Be Enough?

No. Rockwool is very careful to say: “Once ROCKWOOL is fully operational in Ranson, we will consume an average daily total of approximately 1.6MMSCF.”[1] (note: MMSCF is the same as MMcf). That is the average; it includes production start-ups, shut-downs, and malfunctions. The average is like a consumer’s annual heating use bill: higher in the winter, lower in the summer. The yearly average is something in between. Rockwool knows they need to account for not only their average use, but their possible maximum use of natural gas. And Mountaineer Gas certainly knows they need to provide for all of Rockwool’s usage, at all times, and not merely the smoothed-out average.

So, what is the peak usage of natural gas at the Rockwool plant? The answer is given in their Prevention of Significant Deterioration (PSD) air permit, approved by the West Virginia Department of Environmental Protection. In that permit, Rockwool had to state what the maximum annual usage of natural gas would be for all of their energy-using sources at the facility. The data provided to DEP is in units of power, MMBtu per hour, but we show the equivalent natural gas usage in MMcf per day in the table below.

| Rockwool PSD Application 11/17/2017 | Maximum Rated Heat Input per hour | Max. Rated Heat Input per day | Equivalent natural gas volume usage per day |

|---|---|---|---|

| Natural gas combustion units (includes the curing oven, pollution abatement afterburners, and boilers) | 52 MMBtu | 1,248 MMBtu | 1.216 MMcf |

| Melting furnace and Pre-heat burner | 104 MMBtu | 2,496 MMBtu | 2.433 MMcf |

| Total: | 3.649 MMcf |

The maximum usage is 3.649 MMcf per day, which is 2.26 times higher than what Rockwool publically states will be their average daily total. Calculating the hourly rate for that higher usage and we get 3,649 Mcf/day divided by 24 hrs/day = 152 Mcf/hr. Which is a higher flow rate than can be provided via a typical decompression unit at a CNG injection site (remember, they were normally in the 40-75 Mcf/hour range). To service Rockwool during peak demand, Mountaineer Gas will need to build multiple injection sites. That is why they are looking for “two to three CNG sites” in your neighborhood.

[1]www.psc.state.wv.us/scripts/WebDocket.cfm?CaseActivityID=506107&NotType=

High Risk Traffic Accidents

When these trucks are involved in traffic accidents they typically leak fracked gas. This requires at least a half mile radius evacuation. Unfortunately, the leaks cannot always be safely stopped and all the gas must be allowed to leak out before the accident can be cleaned up and the truck safely removed. This necessitates a prolonged evacuation. These evacuations can be very problematic if children are home alone say in the afternoon after school and very disruptive if they occur in the night.

Safety Issues from Onsite Storage

Storage of gas on site creates a risk for leakage and explosion risk. This could lead to severe injuries, death, property damage, and prolonged mass evacuations. Large amounts of gas can leek without detection before ignition causing large explosions and profound damage to property, the environment, and human health.

Who Pays?

Mountaineer Gas saw an opportunity for Berkeley County to be the conduit to supply their new potential customer, Rockwool, in Jefferson County. In 2015, the West Virginia state legislature passed a law that allowed gas companies to charge current rate-payers for the cost of upgrades and extensions from current distributors. This allowed Mountaineer Gas to push the cost of building this pipeline from the existing pipeline in Berkeley County to this new potential customer in Jefferson County on the current ratepayers, not the new potential customer. Mountaineer Gas submitted the PSC tariff request to do just this in 2017, 2018, and continues today. This means that unfortunately, Rockwool contributed $0 to the building of the pipeline and the household rate payer foots the bill.

Take Action!

Tell your local representatives that you do not want these injection stations in your neighborhood! Use the easily personalized letter below to contact your representatives. Taking a minute or two to personalize the letter really makes a difference. Just add a sentence or so at the beginning as to why this matters to you, fill in your name, email and zip code, and press “send email now.” The message will go directly to the Berkeley County Commissioners and the Berkeley County Development Authority Board.