A new Major Air Emission Source is planned in the eastern portion of Berkeley County, and the public has an opportunity to comment on the permit.

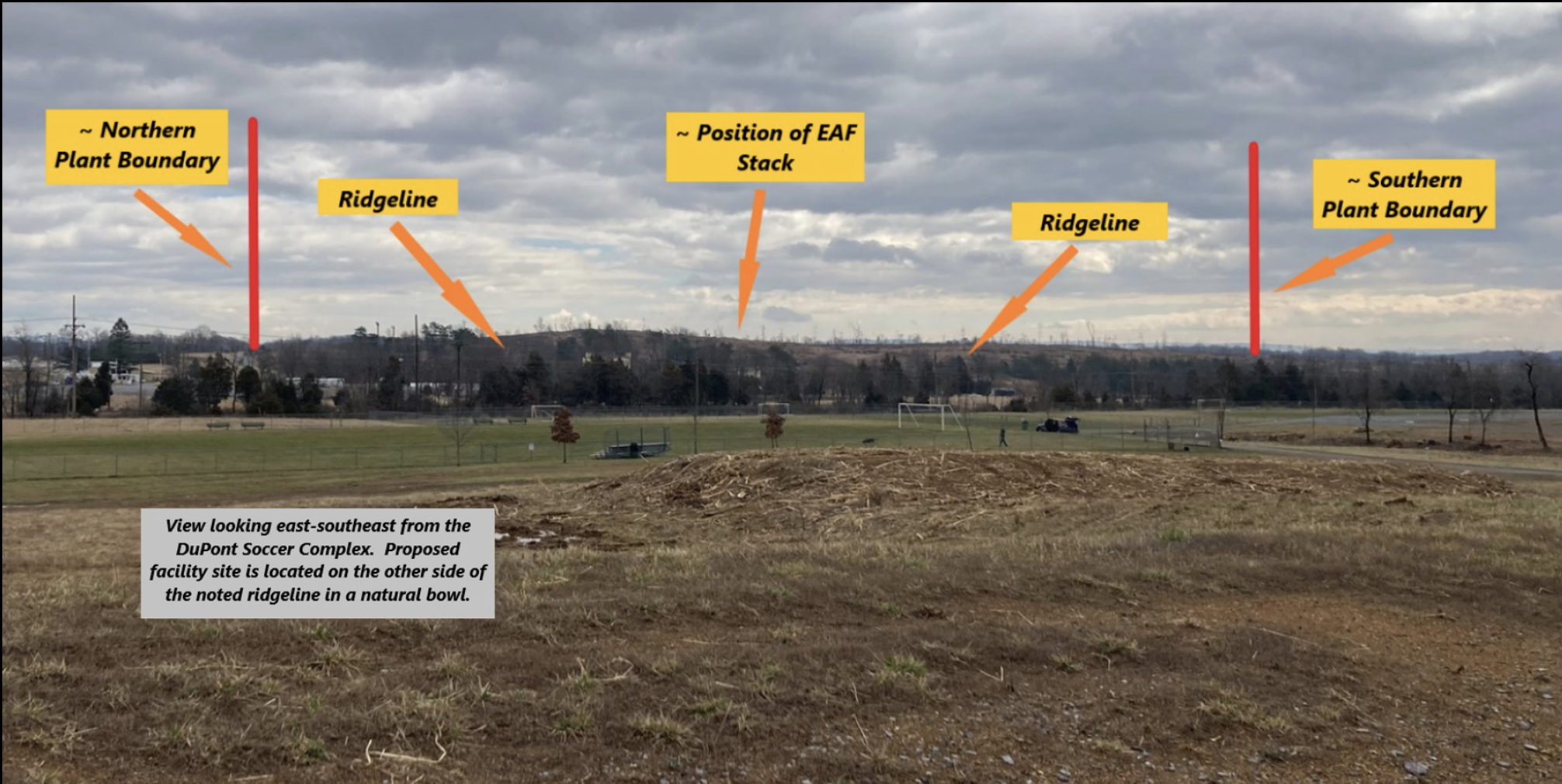

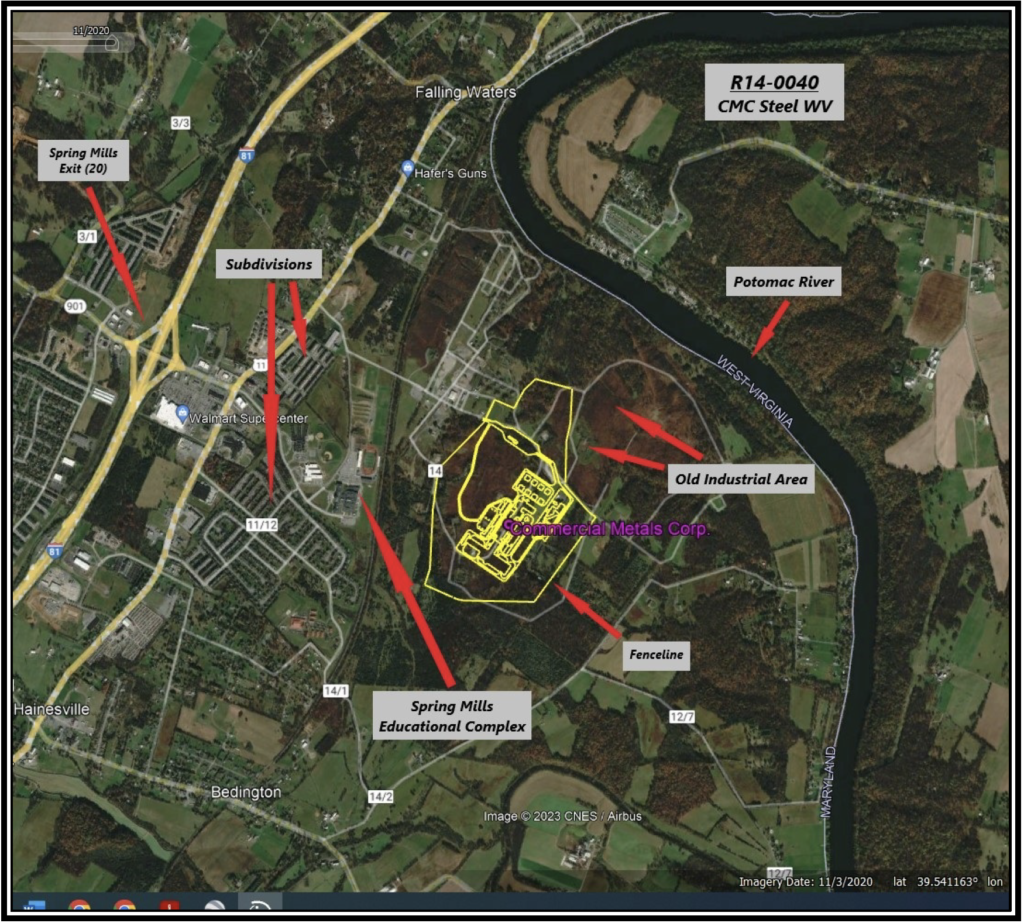

On January 4, 2023, Commercial Metals Company Steel West Virginia (CMC) applied to the West Virginia Department of Environmental Protection (DEP), Division of Air Quality (DAQ) for a permit to construct a steel micro mill located on the old DuPont River Works site at 447 DuPont Road, Martinsburg, Berkeley County.

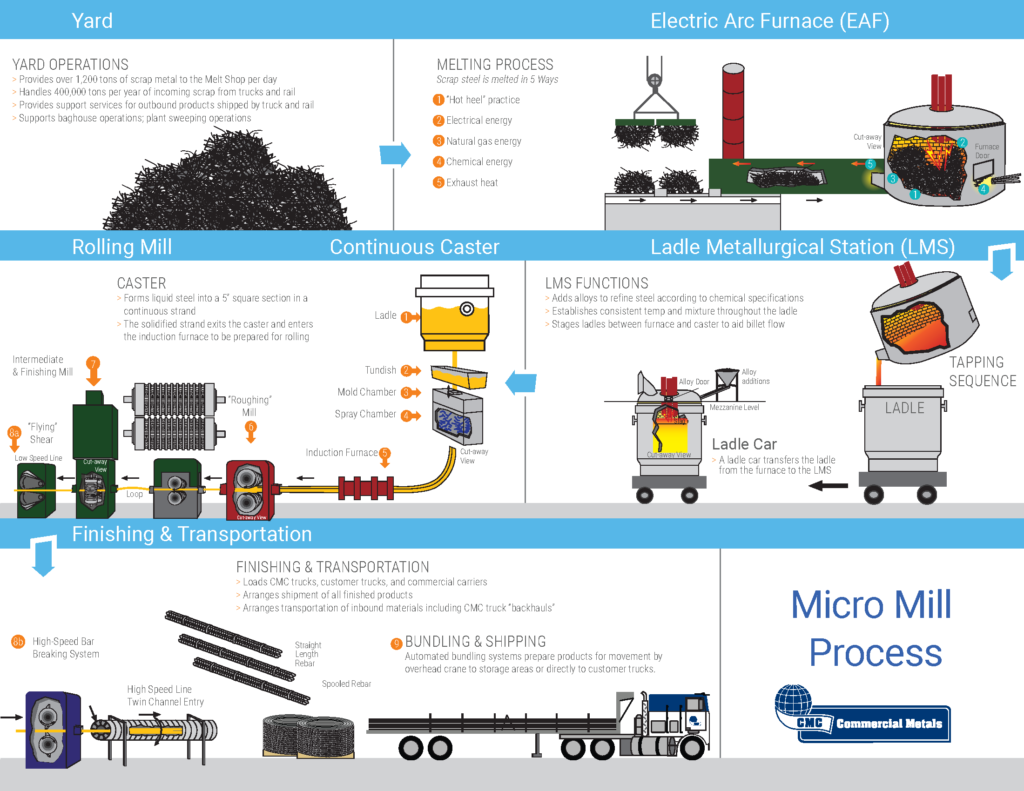

The plant will recycle scrap metal, using it as the sole iron feedstock to make its steel. Sources may include old appliances, machinery, sheet metal, rectangular bundles, and miscellaneous scrap metal. Other materials will be added to the molten steel to remove impurities from the steel through the formation of slag. These materials include but are not limited to coal, petroleum coke, lime, dolomite, and spar.

“The potential emissions authorized by this permit action include: Particulate Matter less than 2.5 microns, 138.61 tons per year (TPY); Particulate Matter less than 10 microns, 145.01 TPY; Particulate Matter (total), 155.20 TPY; Particulate Matter (filterable only), 66.98 TPY; Sulfur Dioxide, 100.70 TPY; Oxides of Nitrogen, 136.82 TPY; Carbon Monoxide, 1,327.93 TPY; Volatile Organic Compounds, 100.50 TPY; Fluorides, 3.29 TPY; Total Hazardous Air Pollutants, 2.84 TPY, Greenhouse Gases (CO2e), 157,635 TPY.”[1]

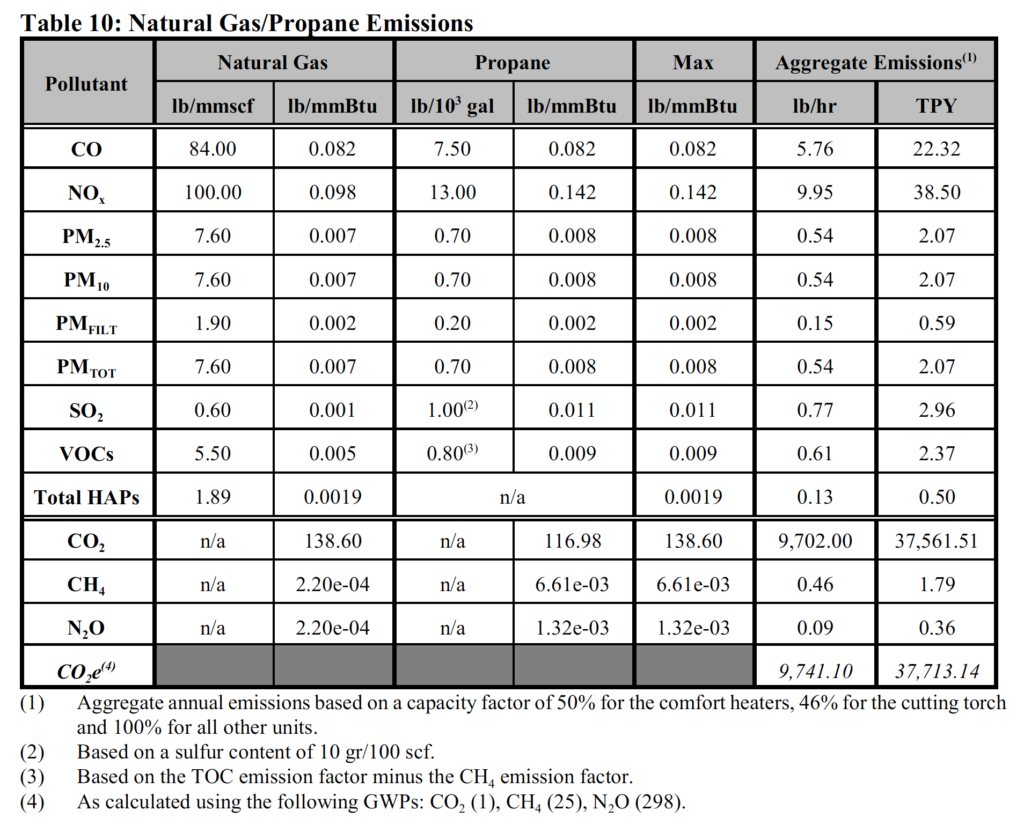

The melting and casting process is the primary source of emissions at the facility. These processes will use high-current electric arcs, natural gas, and oxygen to melt the scrap metal and other components and convert them into molten steel of a specified chemical composition and temperature. A variety of natural gas/propane-fired heaters and dryers are used in this process with associated emissions. Binder used to hold the refractory bricks in the furnaces also give off emissions when the furnaces are hot, and the molten product is also a significant source of emissions.

Below is a table of emissions that are proposed to be permitted and the source in the process.

As mentioned above, a significant amount of slag will be produced as a byproduct from this facility. This slag—once hardened—will be processed onsite in the Slag Processing Plant (SPP). Once cooled and hardened, the slag may be crushed with a ball drop crusher and taken outside for further processing and storage. The slag will be screened and piled for outdoor storage using a six belt conveyer. This system will process up to 65,000 tons of slag per year.

What are our concerns?

- Accurate and adequate monitoring: The air emissions from this plant will affect many residents in both Berkeley and Jefferson County. The Foundation wants to ensure that CMC adheres to its permit and emits as little air emissions as possible. For this reason, we believe that the monitoring the DEP is requiring should be improved, including the requirement of Continuous Emissions Monitoring Systems for the most accurate monitoring.

- Emissions from the Slag Processing Plant: Slag is initially a part liquid product. However, once it hardens and dries, it can emit particulate matter during crushing, screening, and pile activity such as dropping from a conveyer or being moved with a font end loader. Currently, several of these processes occur outside with wetting as necessary being the only control. This may produce polluted runoff and inadequately control particulate matter from these processes.

Public Comment

The DEP has made public a fact sheet on this application. Public comment was accepted by the DEP permit reviewer regarding this matter until June 21. Read the Foundation’s public comment here.

[1] CMC AIR QUALITY PERMIT NOTICE at page 1